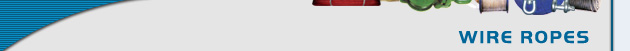

THE DEFINITION OF THE WIRE ROPE

The wire rope is made up of wrapping at least 4 strands around core which is made p.p.c, steel, fiber. Every strands and steels wrapped like helix in a different composition.

LAY OF WIRE ROPE

In general meaning: The wire rope laid in two manners, regular lay and langlay wire rope.

REGULAR LAY WIRE ROPE

The direction of the wire lay in the strand is opposite to the direction of the lay in the rope. It is two kind; right regular lay "s/Z", and left regular lay "z/S" these are constructed like below shapes.

LANG LAY WIRE ROPE

Both strand lay and rope lay are in the same direction.There are two types; right long lay "z/Z" and left lang lay "s/S" these are costructed like below shapes.

MEASURING THE WIRE ROPE

In order to measure the diameter of the steel wire ropes, the folowing certain instructions should be followed; First, a sample of wire rope is holded straight and without any load exerted on it Second, it should be begin at least

1.5 mt. from the end, while mesuring the diameter of the rope. Third, Two measurements are done 1.5 mt. intervals from the two points. Every measurements point should be vertical to each other. Last, real diameter of the steel wire ropes is defined as the average of these four measurements.

As seen below diagrams (1 st diagram is a correct measurement of the diameter and 2 nd. diagram is an incorrect measurement of the diameter of the steel wire ropes). Diameter tolerances for the standard wire rope vary from -%0,+%5 (lower tolerance is -%0, and upper tolerance +%5)

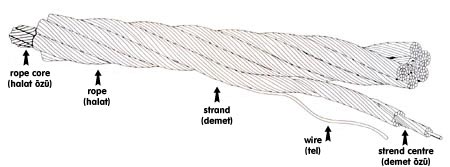

HOW TO UNCOIL AND REWIND THE WIRE ROPE

The uncoiling and rewindding is the most important thing finished wire rope.

If we want to avoid kinks and defects in to the rope it should be considered below illustration.

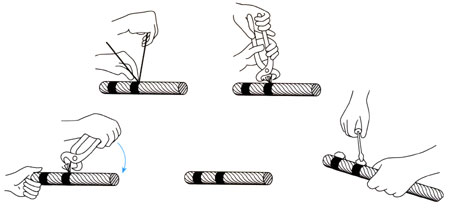

HOW TO CUT ROPE

When we cut the rope we have to wrap both side of rope with low carbon steel wire or pipe clip as shown at the following illustrations.

|